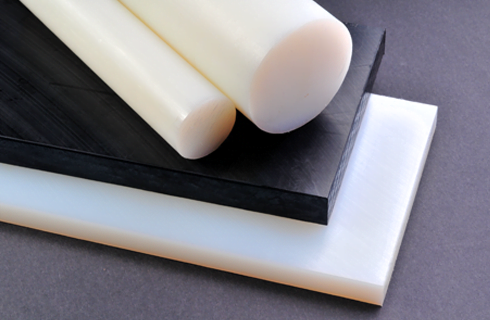

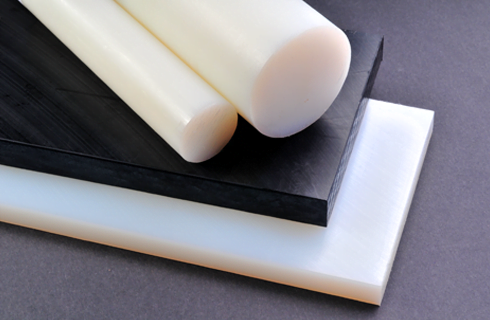

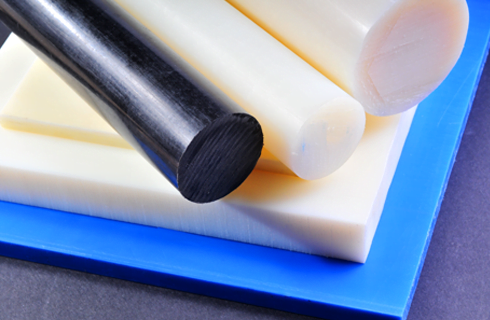

PolyPropylene (PP) Product Description

PolyPropylene (PP) is a thermoplastic polymer used in a wide variety of applications including textiles and automotive components.

It has a high mechanical and tensile strength, resists stress cracking and easy to weld. Furthermore, PP has good chemical and electrical properties that enable it to be used in a wide range of applications.

PolyPropylene (PP) Properties

- Low density

- High head resistance

- High chemical resistance

- Low abrasion resistance

- High tensile strength

Polypropylene (PP) FAQs

What is Polypropylene?

Polypropylene (PP) is a lightweight and durable thermoplastic polymer widely used in a variety of applications, such as packaging, automotive parts, and household goods. It is valued for its excellent chemical resistance and versatility.

What are the key properties of Polypropylene plastic?

Polypropylene plastic offers several desirable properties, including:

•High chemical resistance

•Lightweight and low density

•Good fatigue resistance

•High melting point (160-170°C)

•Excellent moisture resistance

•Cost-effectiveness

What is Polypropylene material commonly used for?

Polypropylene material is used in a range of applications, such as:

•Packaging: Food containers, bottles, and caps

•Automotive: Bumpers, battery cases, and interior trims

•Medical: Disposable syringes, medical vials, and laboratory equipment

•Industrial: Pipes, tanks, and chemical containers

•Textiles: Carpets, ropes, and reusable bags

Is Polypropylene plastic safe for food contact?

Yes, Polypropylene is widely considered safe for food contact applications. It is commonly used in food storage containers, bottles, and packaging due to its non-toxic and non-reactive nature.

How does Polypropylene compare to Polycarbonate?

•Durability: Polycarbonate is stronger and more impact-resistant, making it suitable for protective applications.

•Weight: Polypropylene is lighter and less dense than Polycarbonate.

•Chemical Resistance: Both materials have excellent chemical resistance, but Polypropylene is better suited for corrosive environments.

•Heat Resistance: Polycarbonate has a higher heat tolerance compared to Polypropylene.

•Transparency: Polycarbonate is transparent, whereas Polypropylene is usually opaque.

Can Polypropylene plastic be recycled?

Yes, Polypropylene is recyclable and is identified by the recycling code “5.” Recycled PP can be used in various applications, including non-food containers, automotive parts, and textiles.

What are the advantages of using Polypropylene material in industrial applications?

•Cost-effective compared to many other polymers

•High resistance to chemicals and moisture

•Easy to mold, fabricate, and weld

•Lightweight, reducing transportation costs

How does Polypropylene perform in high-temperature environments?

Polypropylene has a high melting point (around 160-170°C), making it suitable for applications requiring heat resistance. However, for extreme temperatures, materials like Polycarbonate may be more appropriate.

What industries commonly use Polypropylene material?

Polypropylene is widely used in industries such as:

•Packaging

•Automotive

•Construction

•Medical and healthcare

•Textile manufacturing

•Consumer goods production

Where can I find Polypropylene material suppliers in Singapore?

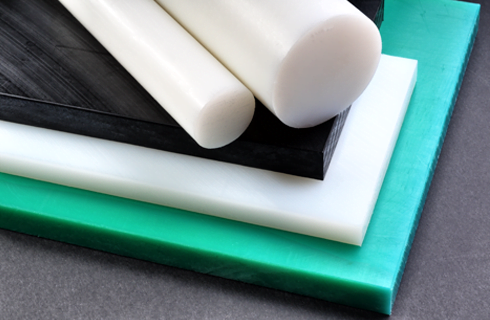

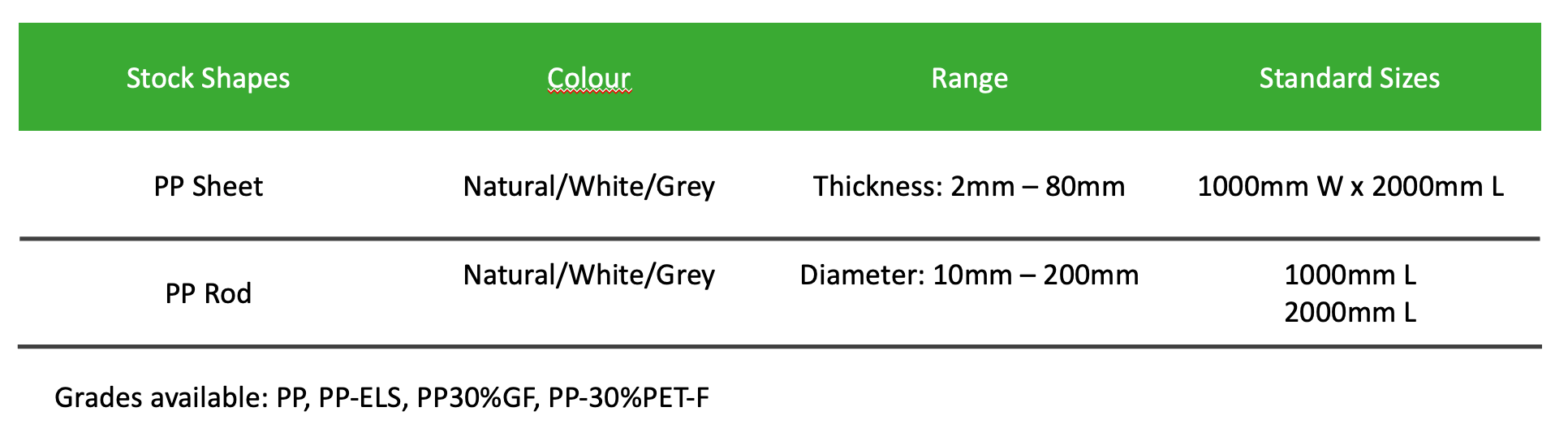

You can source high-quality Polypropylene materials, including sheets, rods, and films, from reputable suppliers in Singapore specializing in industrial and commercial plastics.

General Plastics

At Swees Engineering, we aim to provide you with the solutions that fit your needs perfectly with our wide range of products and services. Contact us today.

Call us

(+65) 6292 5544

Fax

(+65) 6296 6521

Address

48 Toh Guan Road East

#03-140/141 Enterprise Hub

Singapore 608586

[gravityform id="1" title="false" description="false"]

About us

Swees Engineering is committed in delivering high quality products to its clients globally.

Services

- Plastics Division

- Rubber Division

- Customized Services

Contact Us

info@sweesengrg.com.sg

(+65) 6292 5544

48 Toh Guan Road East

#03-140/141 Enterprise Hub

Singapore 608586